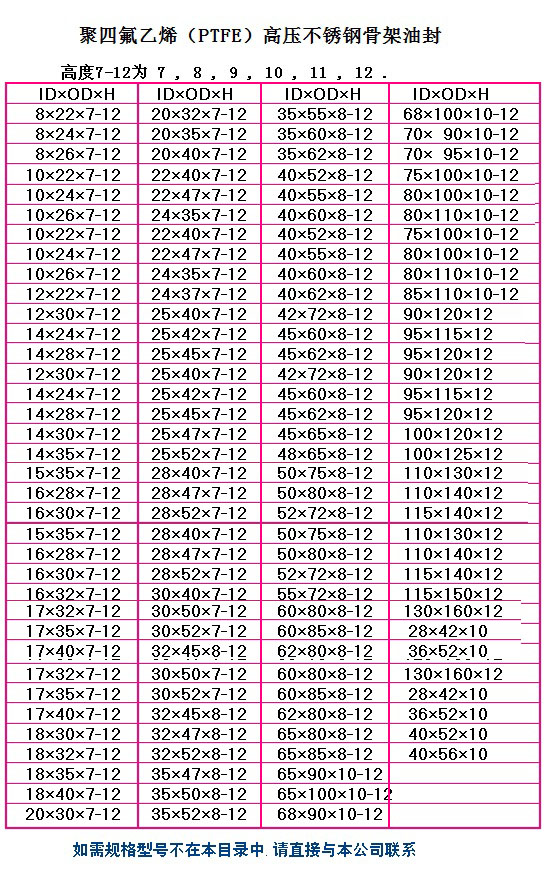

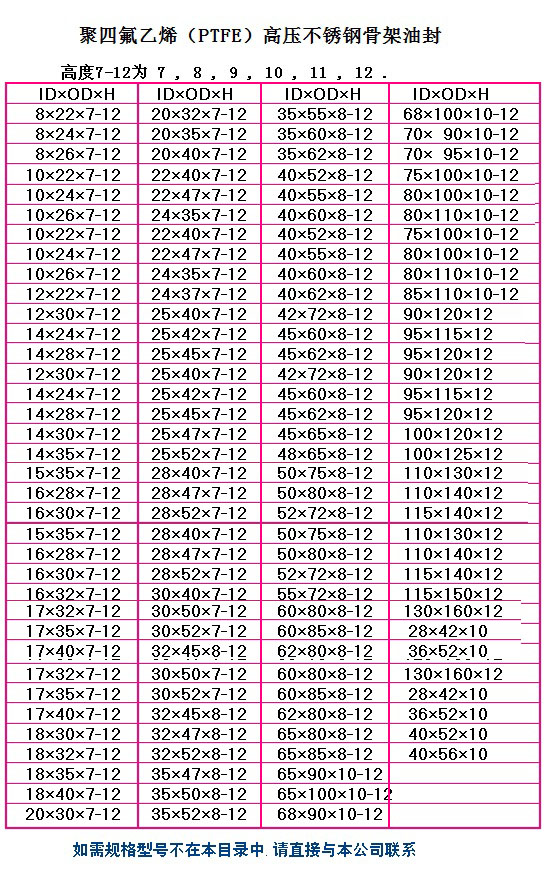

(Teflon) skeleton oil seal. PTFE stainless steel rotary oil seal. PTFE skeleton oil seal. (PTFE) high pressure oil seal. PTFE oil seal

1、 Material advantages:

Polytetrafluoroethylene (PTFE), also known as Teflon or plastic king, is a copolymer of tetrafluoroethylene monomer, which has the following advantages:

1. Chemical stability: almost all chemical resistance, strong acid, strong alkali or strong oxidant and organic solvent do not work on it

2. Thermal stability: the cracking temperature is above 400 ℃. Therefore, it can work normally in the temperature range of - 200 ℃ ~ 300 ℃.

3. Antifriction: the friction coefficient of PTFE material is very low, only 0.02, which is 1 / 40 of that of rubber.

4. Self lubricity: PTFE material surface has outstanding self lubricity, and almost all viscous substances cannot adhere to its surface.

2、 Filling modification:

However, pure PTFE is not wear-resistant. In order to make it practical, it must be filled and modified. We use two methods: one is inorganic filling modification, adding glass fiber, carbon fiber, graphite, molybdenum disulfide, etc. into PTFE. The other is organic

Filler modification, adding polyphenylene grease, polyphenylene sulfide, etc. into PTFE (suitable for water purification, food and drug sealing). Through filling modification, the wear resistance of PTFE is improved by 2000 times, and the rigidity and thermal conductivity are increased, so that the oil seal can meet the requirements of high service life

3、 Sealing principle:

The PTFE oil seal lip is pulled into a horn shape during processing. Because PTFE has the ability of memory contraction after drawing, the friction heat generated in the work will make the lip shrink continuously. Therefore, it will hold tightly on the shaft without the help of the spring, so that there is no gap between it and the shaft surface, and it can compensate for wear.

4、 Product advantages:

Compared with rubber oil seal, polytetrafluoroethylene (PTFE) oil seal has the following advantages:

1. The rubber oil seal adopts the sharp lip pressed by the spring, and the width of the contact surface with the shaft is only 0.3-0.5mm. The PTFE oil seal adopts the wide lip dynamic structure without spring, and the width of the contact surface with the shaft is 5-7mm, which can maintain a sufficient oil film, is not sensitive to the eccentricity of the shaft, and can still work normally under the condition of radial jump of 0.4mm.

2. The inner wall of PTFE oil seal is engraved with a threaded groove opposite to the shaft rotation. When the shaft rotates, an inward thrust will be generated to prevent fluid outflow. This thrust is so high that it can seal the pressure of 1.0MPa (single lip) and 3Mpa (double lip) fluid, and the rubber oil seal is only 0.03mpa

3. PTFE oil seal has excellent wear resistance, especially suitable for working without or with little oil. Even if it is used again after long-term shutdown, it can immediately have low friction characteristics.

4. PTFE oil seal is especially suitable for high-speed rotation applications, with speeds up to 30m / s

5. PTFE oil seal can achieve no leakage. Under the same conditions, the sealing performance is 30 times that of rubber oil seal.

5、 Product application:

PTFE oil seal is mainly used in air compressor, engine, gearbox, motor, pump, air conditioner, mixer, automatic precision machinery, robot, chemical treatment equipment, pharmaceutical and food processing equipment, etc. it is especially suitable for applications that cannot be met by traditional rubber oil seal.

6、 Product picture

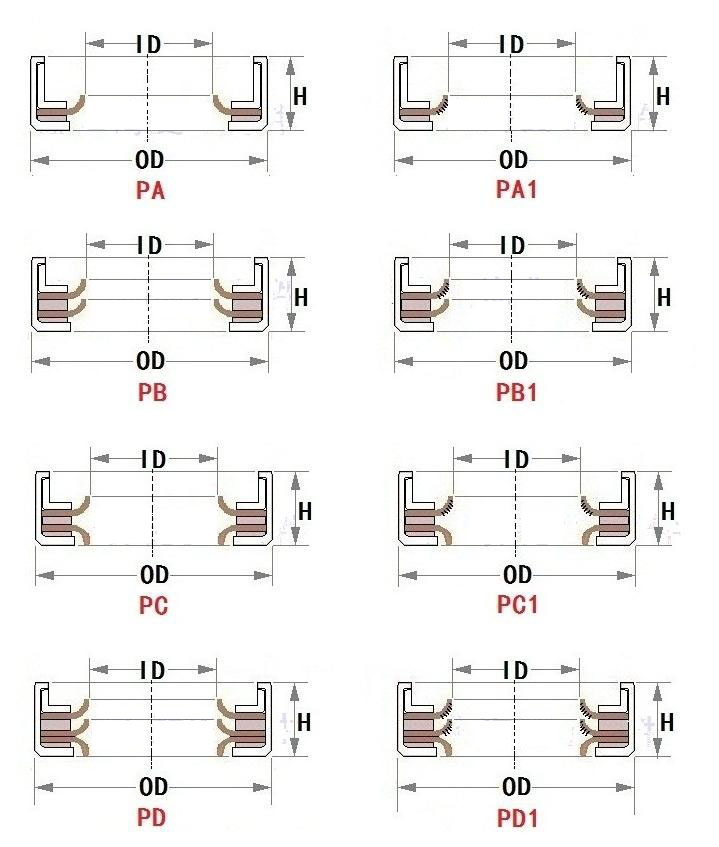

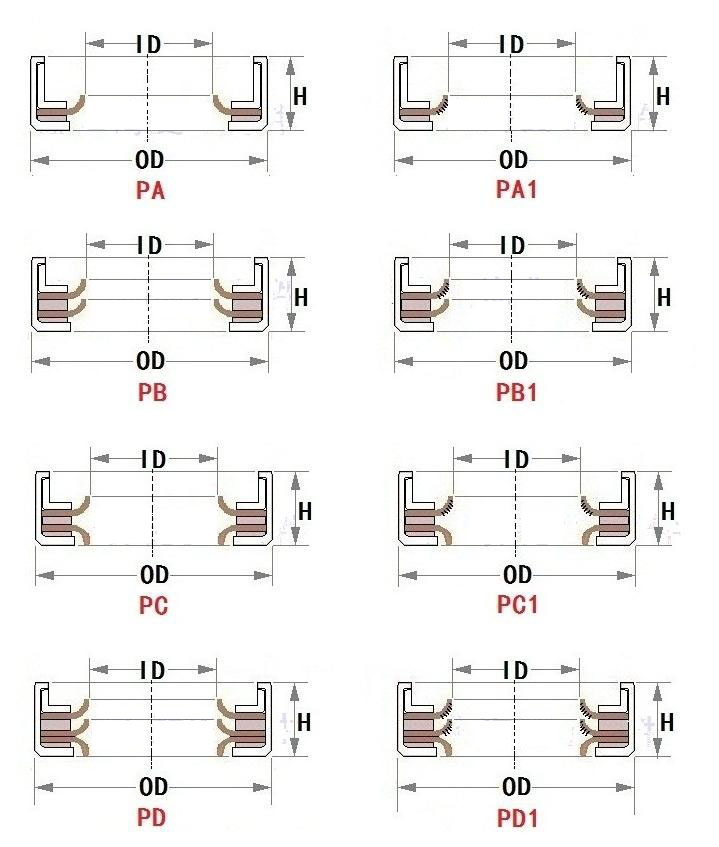

7、 Product classification diagram

service

service